Browsing the World of Fasteners and Machining: Methods for Precision and Speed

In the intricate realm of bolts and machining, the pursuit for accuracy and speed is a continuous challenge that demands precise focus to information and calculated preparation. From comprehending the varied selection of bolt types to picking optimal products that can withstand extensive needs, each step in the process plays a critical role in accomplishing the desired outcome.

Understanding Fastener Kind

When selecting fasteners for a project, comprehending the different kinds readily available is essential for ensuring optimum efficiency and reliability. Bolts are available in a large range of kinds, each made for particular applications and needs. Screws are made use of with nuts to hold products together, while screws are functional bolts that can be used with or without a nut, depending upon the application. Nuts, on the various other hand, are internally threaded fasteners that mate with screws or screws, offering a protected hold. Washing machines are necessary for dispersing the load of the fastener and preventing damage to the material being fastened. Additionally, rivets are irreversible bolts that are perfect for applications where disassembly is not required. Comprehending the differences between these bolt kinds is crucial for choosing the right one for the task, making sure that the link is strong, sturdy, and reliable. By choosing the appropriate fastener kind, you can optimize the efficiency and longevity of your job - Fasteners and Machining.

Picking the Right Products

Recognizing the value of choosing the best materials is paramount in making certain the optimum performance and reliability of the picked fastener kinds went over previously. When it involves bolts and machining applications, the product selection plays a crucial function in establishing the overall stamina, toughness, deterioration resistance, and compatibility with the desired environment. Various materials supply differing residential or commercial properties that can substantially influence the performance of the fasteners.

Common products utilized for fasteners consist of steel, stainless steel, titanium, brass, and aluminum, each having its unique staminas and weak points. Steel is renowned for its high toughness and resilience, making it suitable for a large variety of applications. Picking the best material includes considering variables such as toughness requirements, ecological problems, and spending plan restrictions to make certain the desired performance and durability of the fasteners.

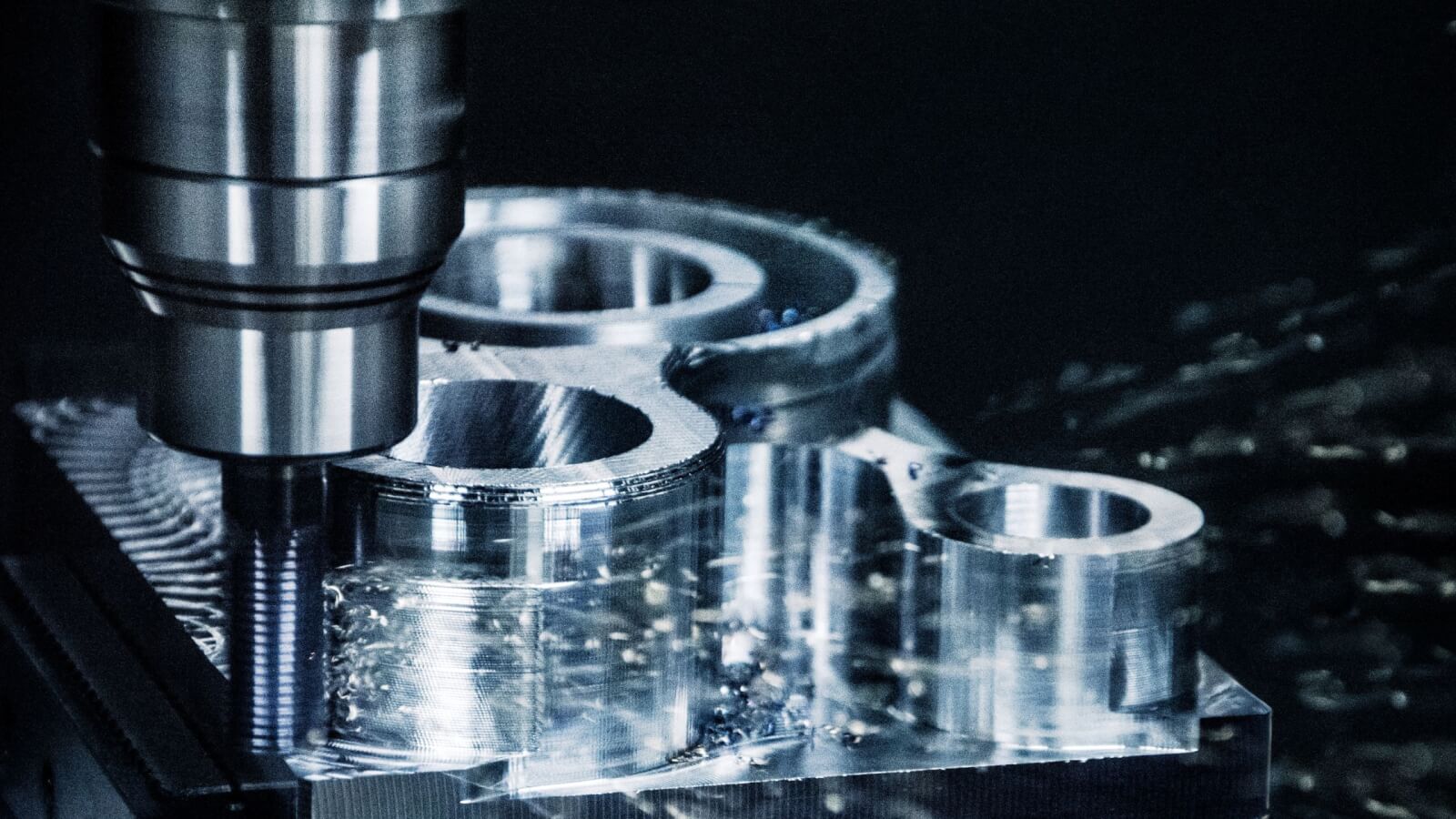

Precision Machining Techniques

In enhancement to CNC machining, various other accuracy techniques like grinding, turning, milling, and exploration play essential duties in fastener production. Grinding assists achieve fine surface finishes and limited dimensional tolerances, while transforming is often used to create cylindrical elements with precise sizes. Milling and exploration procedures are vital for shaping and developing openings in fasteners, ensuring they meet exact specs and function correctly.

Enhancing Speed and Effectiveness

To enhance bolt production processes, it is important to streamline procedures and apply efficient techniques that complement accuracy machining methods. One vital method for enhancing rate and effectiveness is the application of lean manufacturing principles. By minimizing waste and concentrating on constant enhancement, lean practices aid eliminate bottlenecks and optimize workflow. Additionally, investing in automation technologies can substantially increase manufacturing rate. Automated pop over to these guys systems can deal with repeated jobs with precision and speed, enabling workers to focus on even more facility and value-added tasks. Embracing Just-In-Time (JIT) supply management can likewise improve performance by making sure that the appropriate materials are available at the correct time, decreasing excess stock and decreasing lead times. Promoting a society of cooperation and interaction amongst group participants can enhance overall performance by promoting openness, problem-solving, and development. By combining these strategies, producers can attain a balance between speed and accuracy, eventually enhancing their one-upmanship in the bolt market.

Quality Assurance Procedures

Applying rigorous quality control measures is critical in making certain the dependability and uniformity of bolt products in the manufacturing procedure. Fasteners and Machining. Quality control measures include numerous phases, starting from the choice of raw materials to the final examination of the ended up fasteners. This involves assessing aspects such as material resilience, strength, and structure to assure that the bolts fulfill market requirements.

Normal calibration of devices and machinery is important to preserve consistency in production and guarantee that fasteners meet the necessary resistances. Executing rigorous protocols for recognizing and addressing non-conformities or issues is vital in avoiding substandard items from entering the market. By establishing an extensive quality assurance structure, producers can copyright the online reputation of their brand name and deliver bolts that meet the greatest standards of performance and durability.

Verdict

In the complex world of fasteners and machining, the quest for precision and rate is a continuous challenge that requires thorough additional hints interest to detail and tactical planning. When it comes to bolts and machining applications, the product option plays a critical role in figuring out the overall stamina, longevity, deterioration resistance, and compatibility with the designated atmosphere. Precision machining entails various advanced techniques that make sure the tight tolerances and specs needed for bolts.In addition to CNC machining, other precision methods like grinding, turning, milling, and boring play essential duties in fastener production.To optimize fastener production processes, it is crucial to enhance procedures and apply effective strategies that match precision machining techniques.